Jarvis for Warehousing: Re - "AI"maging Warehouse Operations with AI

By tapping into the collective intelligence of a network of warehouses, AI facilitates the sharing of insights, best practices, and innovative solutions across different locations.

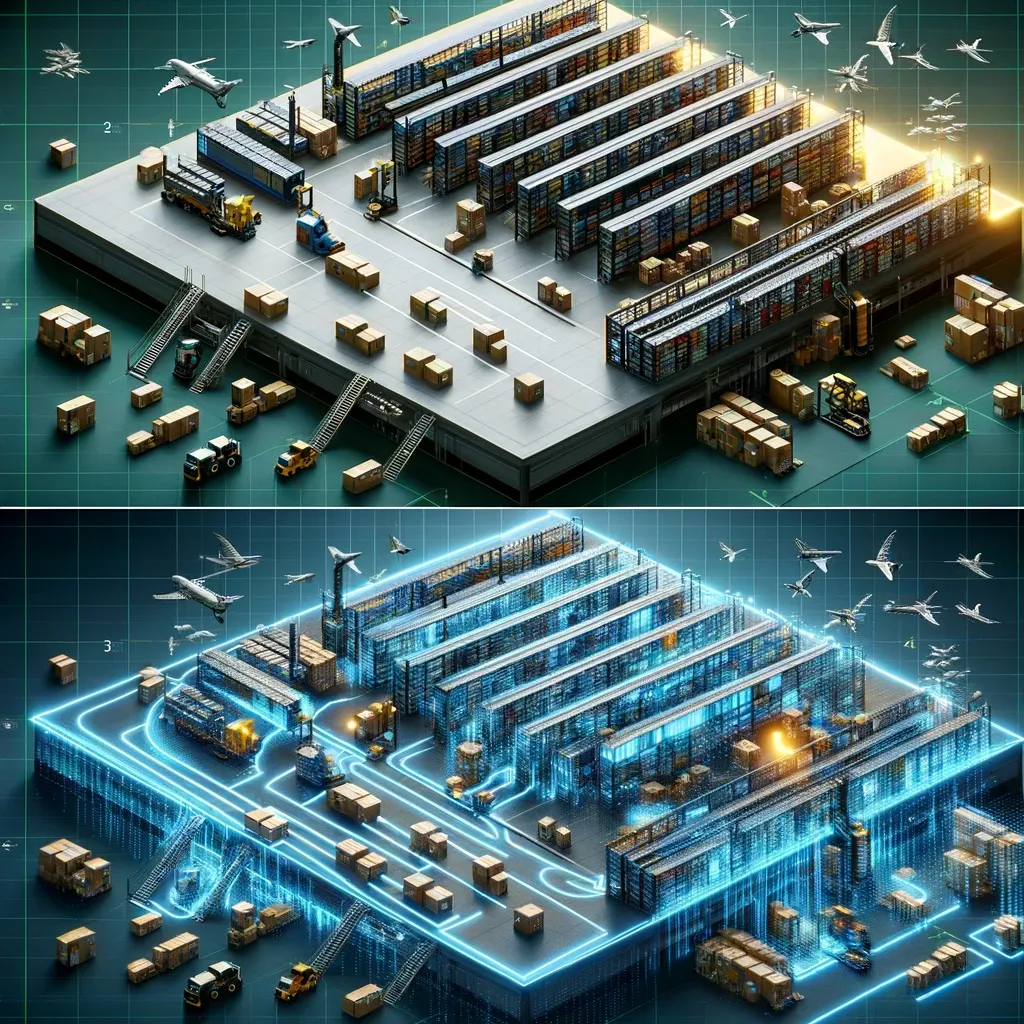

Imagine the backbone of the global economy: warehouses, the silent sentinels of supply chains, pivotal in shaping customer experiences and optimizing business bottom lines.

These aren't just storage units but complex ecosystems ranging from storage warehouses and distribution centers to hyper-local dark stores and automated powerhouses equipped with advanced sorting and retrieval systems.

In this dynamic landscape, AI emerges as a transformative force, leveraging the computational prowess of today’s technology to reimagine warehousing.

This article delves into how integrating Exponential Organization’s SCALE and IDEAS frameworks with AI innovation is not just an upgrade but a complete redefinition of warehousing efficiency and effectiveness.

The Foundation: Data, Workflow, Insights, Integration

Before we venture deeper, let's lay the groundwork. At the core of any system, especially in warehousing, are four pillars:

- seamless data entry

- streamlined workflows

- actionable insights

- robust integration with the wider ecosystem.

These elements form the backbone of an efficient warehousing operation, setting the stage for innovation and optimization.

The Role of Robotics in Warehousing

As the scale of operations at warehouses peaking the role of robots and automation has also sky rocketed in the last decade. Robotics is not just a part of the warehouse; it's becoming the heart of many operations.

From Kiva's autonomous mobile robots navigating aisles to AS/RS systems that store and retrieve items with precision, robotics enhance efficiency and accuracy. Conveyor belts, pick-to-light systems, and sort-by-light technologies further streamline processes, revolutionizing warehouse operations.

So it's clear that we need to be able to handle Humans, Robots, and Automation systems along with goods & storage systems.

But what is being used to do so today? read on to know more.

Understanding Warehousing Systems: WMS, WCS, and Beyond

To fully appreciate the transformation AI brings, it's crucial to understand the existing landscape of warehousing systems. Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS) serve as the digital backbone, managing inventory and coordinating the movement of goods.

While WMS is an overall system that handles the storage, picking, putaway, etc., in the warehouse, WCS/WES is a system that controls the automation + robots.

These systems, while effective, are evolving with AI's integration, leading to unprecedented levels of efficiency and insight.

The AI-Driven Paradigm Shift in Warehousing:

AI isn't just enhancing warehousing operations; it's revolutionizing them. Let’s explore how each innovation aligns with the ExO's SCALE and IDEAS frameworks:

Conversational Interfaces and Dashboards: (Deriving from ID of IDEAS)

With the advent of LLMs, making conversational interfaces is now possible. These interfaces revolutionize how warehouse staff interact with systems, making technology accessible through natural language processing.

This innovation significantly reduces training time, as employees can communicate with the system using voice commands or text inputs, just as they would with another human.

It enhances operational efficiency by allowing quick and natural interaction, leading to faster problem resolution and task execution.

Key Benefits:

Reduced Training Time:

Intuitive voice and text commands simplify system interactions, making it easier for new staff to become proficient.

Increased Efficiency:

Immediate responses to queries and commands accelerate decision-making and task completion.

Improved Accessibility:

Makes technology usable for a diverse workforce, including those with limited reading skills or those who are not native speakers of the warehouse's primary language.

Dashboards:

AI-driven dashboards offer a real-time, comprehensive view of warehouse operations through easily digestible visualizations.

Managers can quickly assess performance, identify bottlenecks, and make informed decisions without sifting through complex reports.

Customizable views ensure that each user can focus on the metrics that matter most to their role, fostering a proactive approach to warehouse management.

Key Benefits:

Real-Time Decision Making:

Instant access to key performance indicators allows for swift adjustments to operations, enhancing responsiveness.

Customizable Views:

Tailored dashboards mean that relevant insights are always front and center, eliminating information overload.

Proactive Problem Solving:

Visual trends and alerts help identify issues before they escalate, enabling preventive measures.

Data Insights and Autonomy: Empowering Precision and Proactive Operations

Small Models and Orchestration:

Orchestrating small, finely tuned AI models & several Narrow Models as need be for specific warehouse tasks brings unparalleled precision to operations.

This approach allows for a granular level of control and optimization, from managing inventory to optimizing the logistics of order fulfillment.

The ability to fine-tune and combine these models means that warehouses can adapt more quickly to changing conditions, improving overall efficiency and reducing waste.

Key Benefits:

Granular Optimization:

Tailored models for specific tasks lead to more accurate and efficient operations.

Adaptive Operations:

The system can quickly adjust to changes, whether in order volume, inventory levels, or operational disruptions.

Enhanced Collaboration:

Orchestrated models work in harmony, ensuring that improvements in one area benefit the entire operation.

Autonomy in Decision-Making:

Granting AI systems a level of autonomy in decision-making streamlines operations by automating routine decisions, such as reorder points for inventory or assigning tasks based on worker availability and skillset.

This autonomy not only boosts operational efficiency but also allows human staff to concentrate on strategic initiatives, knowing that the AI is managing day-to-day decisions effectively.

Key Benefits:

Reduced Manual Oversight:

Automating routine decisions frees up human resources for more complex and strategic tasks.

Continuous Improvement:

AI systems learn and improve over time, making more informed decisions and further enhancing efficiency.

Scalability:

Autonomous decision-making capabilities allow the system to manage increasing complexity without proportional increases in staffing.

Workflow Automation: Streamlining Operations and Enhancing Productivity

AI-driven workflow automation encompasses the digitization and optimization of routine tasks and complex processes within the warehouse.

By leveraging AI, tasks such as order picking, inventory restocking, and even customer communication can be automated, leading to significant improvements in efficiency and accuracy.

This technology ensures that operations are streamlined, reducing manual errors and enhancing overall productivity.

Key Benefits:

Increased Operational Efficiency:

Automates routine tasks, allowing staff to focus on higher-value activities, thereby increasing overall productivity.

Reduced Error Rates:

Minimizes manual input and intervention, leading to fewer errors in order processing and inventory management.

Enhanced Scalability:

Easily scales operations to handle peak periods without the need for proportionally increasing the workforce.

Optimization Across the Board: Dynamic and Continuous Improvement

Dynamic Optimization: Utilizing AI for dynamic optimization means that warehouse operations can continuously adapt and improve based on real-time data. This encompasses everything from inventory layout optimization to the most efficient routing for picking orders.

AI's ability to analyze vast amounts of data in real-time allows for decisions that not only optimize current operations but also anticipate future needs and adjust accordingly.

Key Benefits:

Adaptive Operations: Real-time adjustments ensure that warehouses can respond quickly to changes, whether in demand, supply, or internal workflows.

Maximized Space Utilization: AI algorithms optimize storage layouts and picking paths, enhancing the use of space and reducing waste.

Future-Ready Decision Making: Predictive analytics empower managers to make informed decisions that anticipate and cater to future operational needs.

Collective Intelligence: Leveraging Networked Insights for Global Efficiency

By tapping into the collective intelligence of a network of warehouses, AI facilitates the sharing of insights, best practices, and innovative solutions across different locations. This approach not only accelerates problem-solving and innovation within individual warehouses but also elevates operational standards across the entire network, ensuring consistent efficiency and quality.

Key Benefits:

Accelerated Innovation: Shared learning and insights drive faster innovation, solving common challenges and implementing best practices more broadly.

Standardized Excellence: Enables a uniform level of operational efficiency and service quality across all warehouse locations.

Enhanced Problem-Solving: Collective data and experiences offer a richer basis for AI models to predict, diagnose, and solve operational issues.

Real-Time Monitoring and Digital Twins: Achieving Transparency and Proactivity

Real-time monitoring, powered by AI, offers an unprecedented level of visibility into warehouse operations, allowing managers to track workflows, inventory levels, and employee performance as they happen.

Digital twins take this a step further by creating virtual replicas of warehouse operations, enabling managers to simulate changes, predict outcomes, and implement improvements with confidence, without disrupting actual operations.

Key Benefits:

Enhanced Visibility: Provides a comprehensive, real-time overview of operations, allowing for immediate identification and resolution of issues.

Informed Decision-Making: Simulations and predictive analytics enable proactive adjustments and optimizations, reducing risk and improving outcomes.

Operational Experimentation: Digital twins allow for risk-free experimentation with layout changes, process adjustments, and new technologies, fostering a culture of continuous improvement.

Conclusion: Embracing the AI-Driven Future of Warehousing

As we explore the myriad ways AI and robotics are transforming warehousing, it's clear that this is just the beginning. By aligning with the principles of Exponential Organizations, warehousing operations are set to become more efficient, responsive, and innovative.

The future of warehousing is here, marked by AI-driven efficiencies, robotics precision, and a commitment to continuous improvement and innovation. Welcome to a world where warehousing operations are not just about storage but about setting new standards in efficiency and responsiveness.

Feel free to reach out to me in case of any inputs or queries at sriharsha.vellanki.nitie@gmail.com.

Exponential Organizations 2.0: The New Playbook for 10x Growth and Impact

Best-selling authors Salim Ismail, Peter H. Diamandis, and Michael S. Malone collaborated with more than 80 global OpenExO community members to create this second edition. You can purchase the book on Paperback, Hardcover, and Kindle.

ExO Insight Newsletter

Join the newsletter to receive the latest updates in your inbox.